March 12, 2021 [Madesta] – Today, we are positive. We have greeted January-February 2021 with 5 projects in Europe, Latin America and Africa and Uruguay, as the turning point of a foreseeable excellent year. Of course, this is not only the markets’ growth, but also the award for the team homework was done in 2020.

On New Year’s Eve 2019, after a record 17.8 million EUR in sales from Madesta, we were excited to start a year far better. 2019 meant an expansion worldwide. With projects all over Europe, the Americas and Africa, the perspective of sustainable growth in Oil & Gas storage terminals seemed to be a reality. Then COVID-19 came along and dramatically changed everything.Oil barrel price fell drastically as COVID altered the very fabric of our lives. In spite of that, Madesta was awarded with several projects in Europe and Africa at the beginning of the year. In times of crisis, all market players have minimal prices, everyone wants to win the project and load their capacities. But during these periods, the most important advantages are: quality, experience, stability and reliability.

Madesta has over 20 years of successful experience in the global market, with about 500 thousand tons of prefabricated steel supplied. If we count the number of projects that we have satisfied this time, then there are more than 150 of them. It’s simple, you do your job well and you are trusted. So our facilities worked steadily and continued to fulfill all obligations.

Oil market recovered as always. We were waiting for this, so even during periods of flat market in spring, we continued active communication with clients. We not only discussed the situation with the pandemic, but also looked for ways to optimally solve project problems together with clients.

For example, in one project, Madesta was able to come up with a solution that reduced the weight of parts for a tank farm by 2.5%. As a result, on the rise of the market, we were able to receive many orders and at the end of the year our sales came close to the indicators of the previous year. So, in 2020 we supplied steel products to 12 countries. Deliveries to Libya and Senegal were for the first time.

We want to simplify our clients’ activity by being closer to them and supporting them as a whole. In that direction we started to provide an integral approach and design optimization in the tank industry since 2020.

To go beyond plates and offer integral supply of all tank components is one of our focuses. Throughout the years we developed an efficient business model that gives us cost wise competitive advantages. Now Madesta has the opportunity to show you this by supplying profiles and accessories.

We took the next step towards meeting new opportunities in Eastern Europe. Eastern Europe is one of promising markets. The Polish market, is the largest in the region, is full of storage tank projects.

Madesta was systematically working in this direction and in 2020 received two certificates from local institutions UDT and TDT confirming the quality and ability to produce and supply parts for tanks. This opened up opportunities for Madesta to be involved for many projects in Poland.

Madesta never stopped. We have not only executed our jobs, with our traditional good performance, but we have prepared ourselves to cover new markets like LNG and LPG along with our traditional core business.

In 2020 we started work with stainless steel and supply tank parts to Western Europe, which in my opinion deserves a special emphasis. Stainless steel and steel with a 9% Ni content will be in demand primarily in LNG projects. In addition, the hydrogen segment is developing rapidly.

This direction seemed long-term prospects last year, but we already see active investments in this direction.

Tanks for storing liquid hydrogen are even more metal-intensive than LNG and use a large amount of stainless and nickel-containing steel.

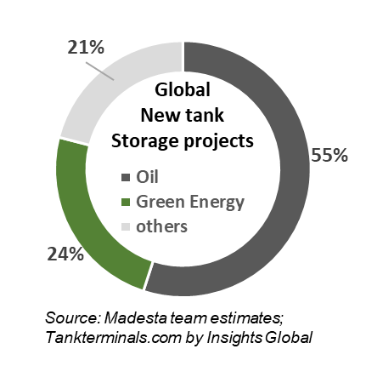

According to our estimates, the share of green energy new projects (LNG and hydrogen) in the next 3 years will be about 24% (in terms of metal consuming for the tanks construction).

Based on the work done in 2020, plans for 2021 and of course market dynamics, Madesta’s team conservative goal is to increase sales by 30% in 2021. Two big projects are already contracted in February, and this is just the beginning of 2021.

Europe, the Americas, Africa and the Middle East are promising for Madesta. Investments on hold for one year are about to be retaken in those regions. It’s time for storage, it’s time for Madesta Steel Prefabrication.

For more information, please contact us.

Antonio Nombela

Business Development Director

tel. +34 607 768 114

Antonio.nombela@madesta.com